Manufactory(CDMO)

Process & Quality

The company's commitment to quality is encapsulated in the principles of "Innovative Research and Development, Professional Manufacturing, and Excellent Quality." We are dedicated to transforming biomedical technology into medical products, fostering a global healthcare platform, and providing medical technological services to enhance the quality of human life.

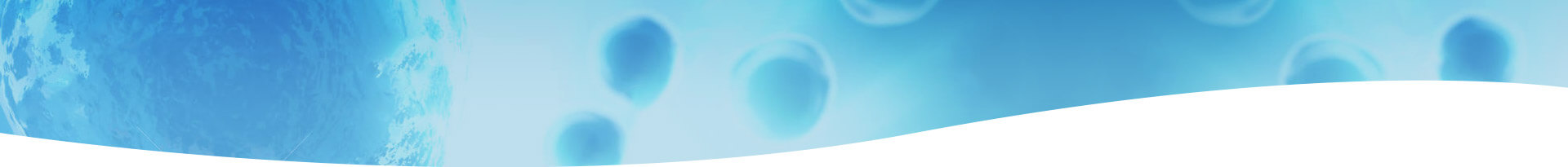

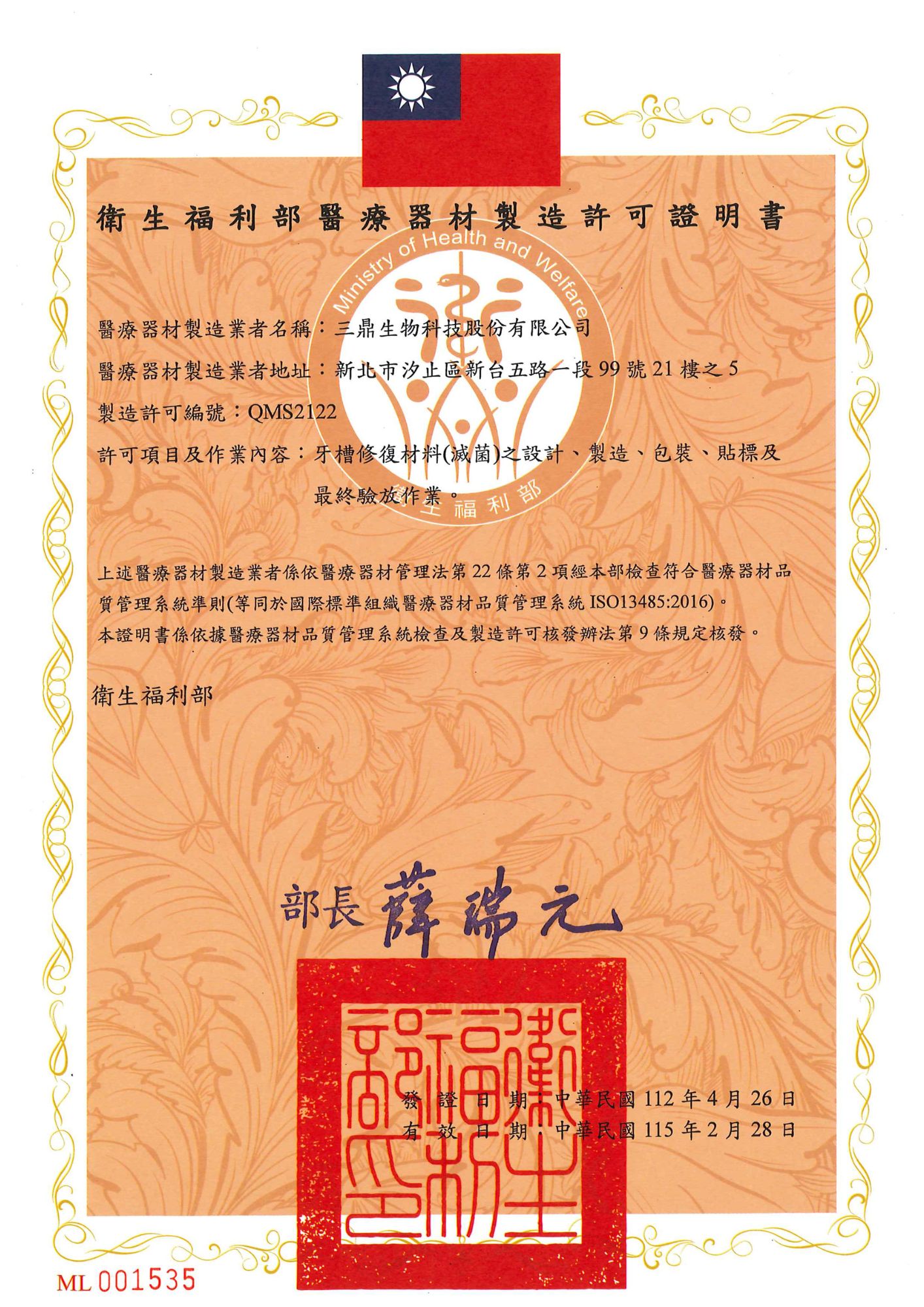

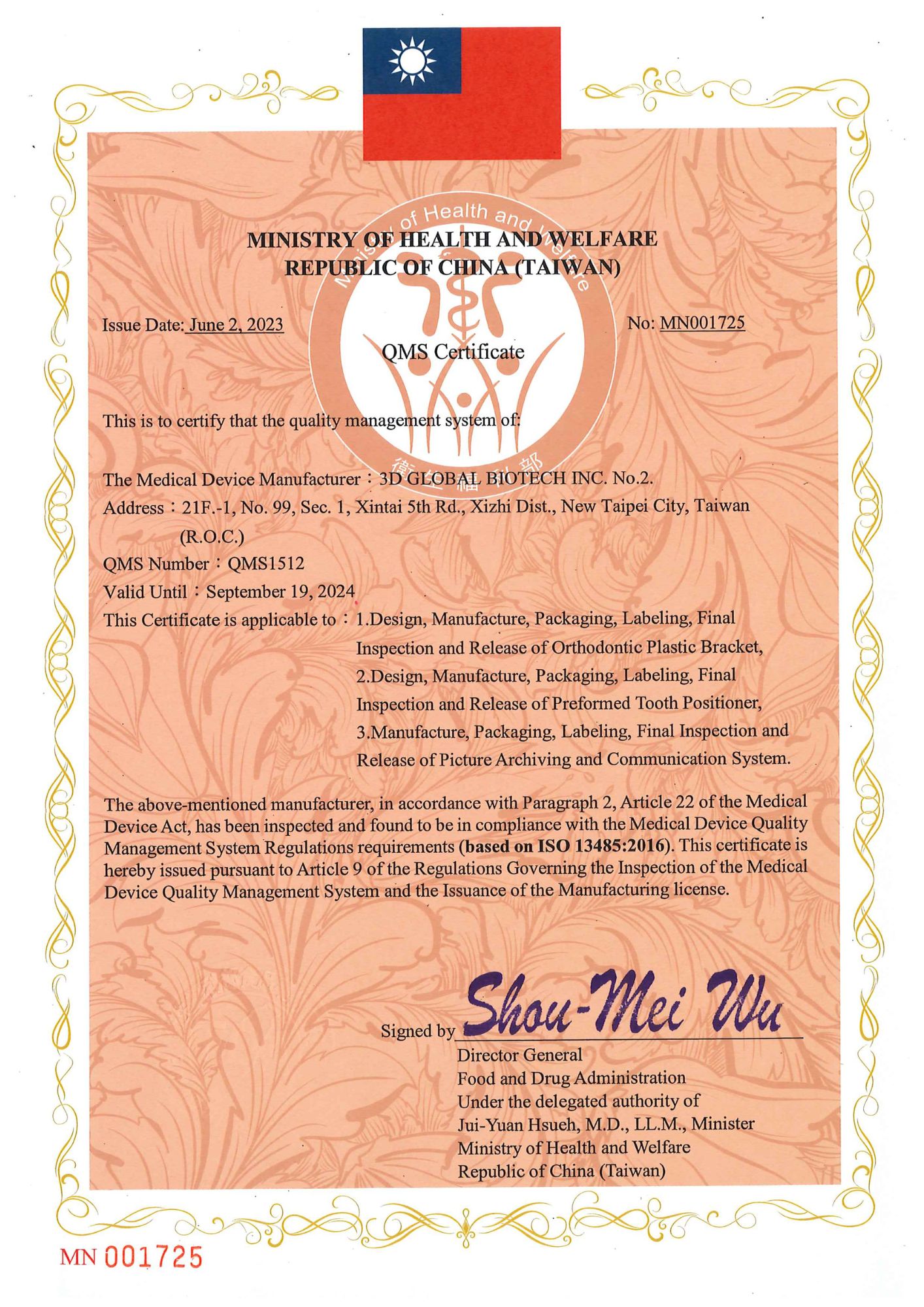

3D Global Biotech has implemented standardized processes and procedures to enhance operational efficiency. Through clear work guidelines and execution specifications, the company minimizes errors, reduces redundant tasks, and avoids resource wastage, thereby increasing productivity and efficiency. As a medical equipment manufacturer, 3D Global Biotech has established a quality management system in accordance with the Medical Device Quality Management System Standard (equivalent to the International Organization for Standardization ISO 13485:2016). The company has successfully passed inspections by the Ministry of Health and Welfare, obtaining a manufacturing license certificate. Our products have also obtained medical equipment licenses in Taiwan and received the U.S. 510K clearance, and five products "G-Be-Bite Dental hand instrument"、"G-Be-Bite Endosseous dental implant accessories"、"G-Be-Bite Intraoral dental drill"、"G-Dredg"Oral Airway Assist" and "G-Dredg"Nasopharyngeal airway" passed FDA Class 1 approval. Relevant certifications include the Ministry of Health and Welfare's Good Manufacturing Practice (GMP) certificates: GMP1426, GMP1512, GMP1753, and the Quality Management System (QMS) certificates: QMS1512, QMS2122.

Capacity and Cases

3D Global Biotech Inc. is a professional medical device manufacturer and a CDMO (Contract Development and Manufacturing Organization) company, offering ODM/OEM services for medical device and cosmetics. Our services encompass product development, manufacturing, packaging, as well as related quality control and regulatory compliance. By outsourcing tasks to us, clients can focus on their core business while benefiting from the expertise and facilities of our research and development team, ensuring smooth product development and manufacturing. 3D Global Biotech Inc. possesses advanced packaging (filling) machinery, including fast sealing machines, high-efficiency bubble cover sealing machines, and vacuum packaging machines. In terms of processing machinery, we have various equipment such as high-temperature furnaces and ovens to ensure proper handling of products during the manufacturing process. We also provide comprehensive production support, including sterile workstations, high-temperature and high-pressure sterilization containers to ensure optimal disinfection, as well as auxiliary equipment like air compressors and pure water manufacturing machines.Here are some collaborative successful cases:『Artificial dental implant device』,『Cardiovascular stents』and『Dental implant instruments』for Sentronic International Corp.;『Breast lesion screening devices』for Thermovision Biotek Inc.;『Orthopedic and dental bone substitutes』for Popeye Marine Biotechnology Limited.;『Digital scanning equipment』for What's Up Technology, Inc.; and『The development of functional contact lenses』for Innova Vision Inc.

Media reports

The spirit and philosophy of 3D Global biotech is a management method with continuous improvement and customer satisfaction as its core. The primary goal is to meet the needs and expectations of its customers.The spirit and philosophy of 3D Global biotech is a management method with continuous improvement and customer satisfaction as its core. The primary goal is to meet the needs and expectations of its customers.